Are you ready to explore how we can help you?

Our world-class experts are available to help find answers to your toughest questions.

Color occurs when light is perceived by the human eye. Color reflected from, or emitted by samples can be measured using basic color meters or more robust spectral devices for more detailed analysis.

Accurate color measurement depends on the sample, on calibrating the setup for the illuminant and detector being used, and on subjective human perception. Also, measurement geometry is critical to ensure consistent results and compliance with standards. Managing each element involves subtleties that are critical for producing accurate, repeatable results.

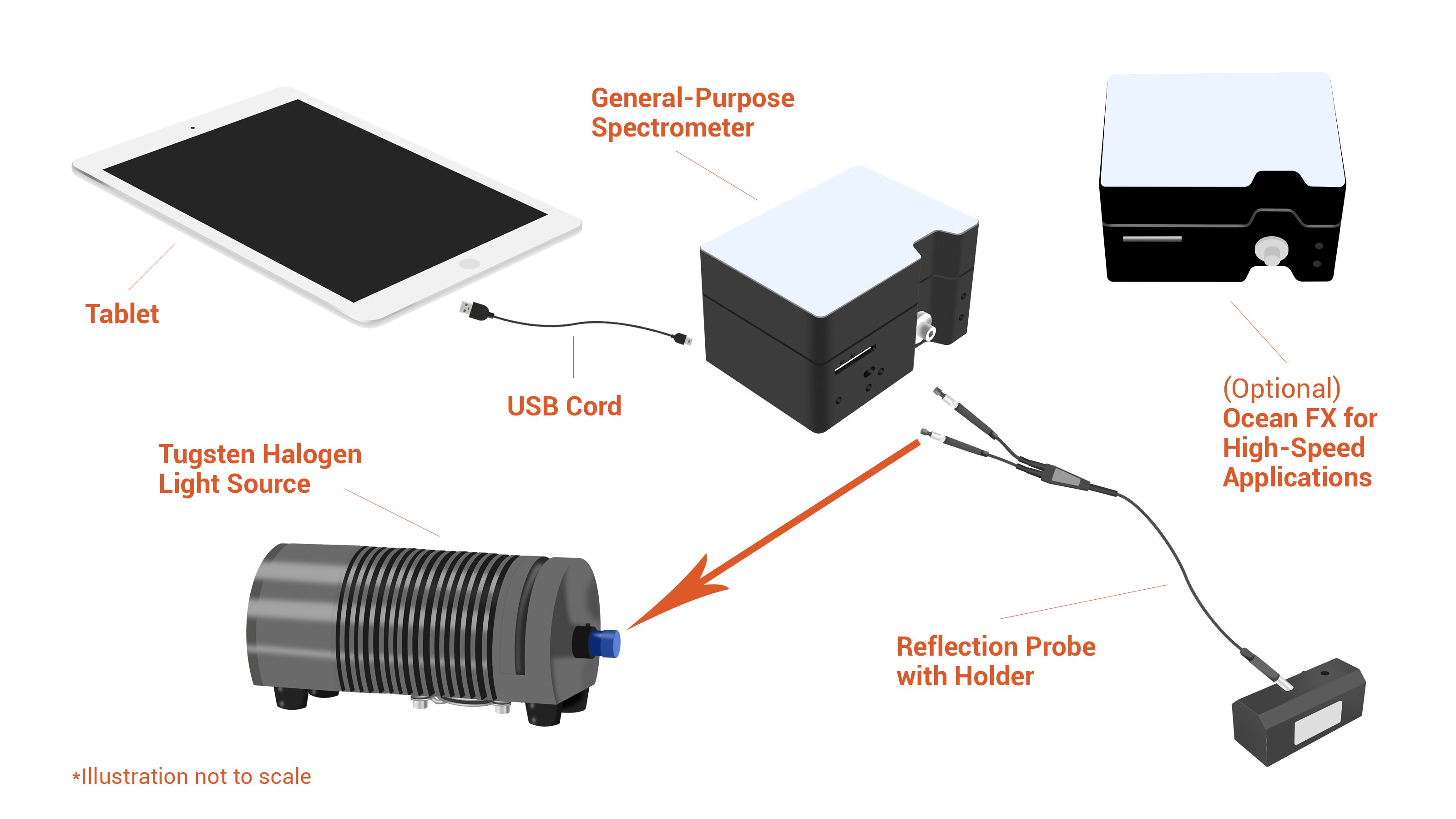

A general-purpose spectrometer like the Ocean HR or Ocean HDX is a good choice for color measurements, with the ultra-compact Ocean ST a good option for integrating in industrial applications. Complete your system with an application-appropriate combination of light source, sampling optics, reflection standards and operating software.

Also, consider our Ocean Applied group for customized, industrial-grade color measurement systems for inline monitoring.

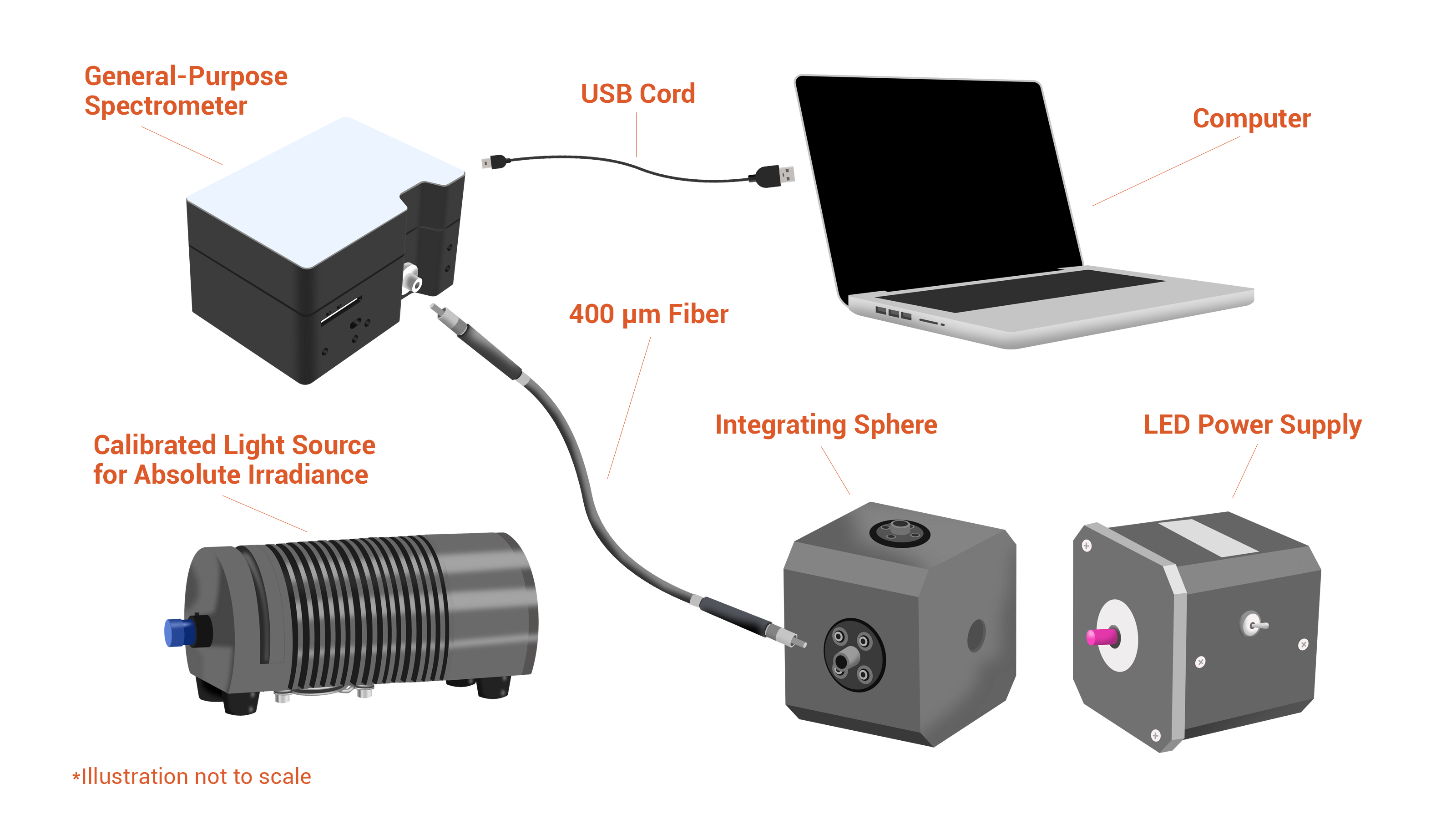

When measuring the color output of an LED, digital display or other emissive source, you’ll need sampling optics like an integrating sphere to collect the emitted light from sample and route it to the spectrometer. Also, you’ll need to calibrate the spectrometer to have an accurate scale for the spectrometer response at each wavelength.

SR and HR series spectrometers deliver varying combinations of high resolution, high speed spectral acquisition and excellent SNR performance to meet your application needs.

Click on this link that will take you to a roundtable discussion. You’ll hear our experts describe the basics of color, differences in emissive and reflective color measurements, and color applications that transcend aesthetic considerations.

Our world-class experts are available to help find answers to your toughest questions.