Are you ready to explore how we can help you?

Our world-class experts are available to help find answers to your toughest questions.

Optical oxygen sensors comprise an indicator fluorophore in a sol-gel host matrix that’s applied to an adhesive patch or fiber tip. The indicator changes optical properties in response to analytes in its environment and a fluorometer measures the response.

Ocean Optics optical oxygen sensing materials can be applied to various surfaces including probes and patches, making them customizable to each application. Because the sensors consume no oxygen, they can be used in continuous contact with viscous samples. Also, unlike oxygen electrodes, optical oxygen sensors do not require continuous stirring.

Learn how you can overcome the limitations of electrochemical-based oxygen and pH sensing with Ocean Optics solutions and simple use of optical oxygen and pH patches.

Watch as Senior Application Scientist Derek Guenther describes the NeoFox optical oxygen sensor and demonstrates how it measures changing O2 levels within a plane cabin as altitude changes.

Learn how Ocean Optics provides O2 sensing calibration routines tailored to your sample environment. Ensure confident results with every measurement.

Options available

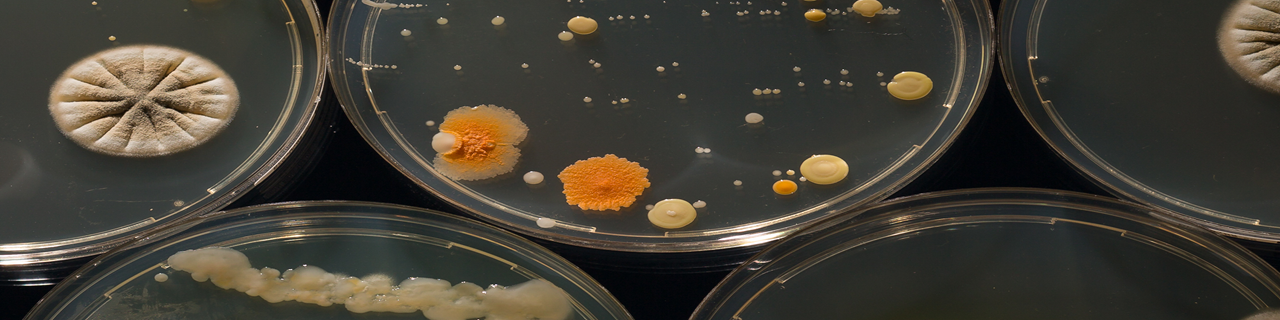

Optical Oxygen Sensing Systems are ideal for biological, environmental, and industrial applications.

Prices From $3,727.00

Our world-class experts are available to help find answers to your toughest questions.