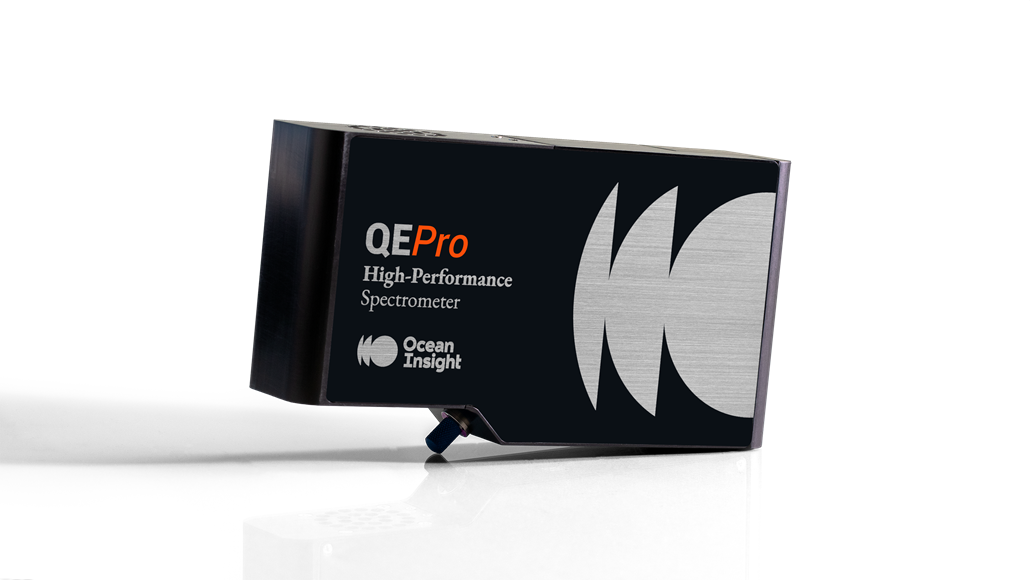

Product Details

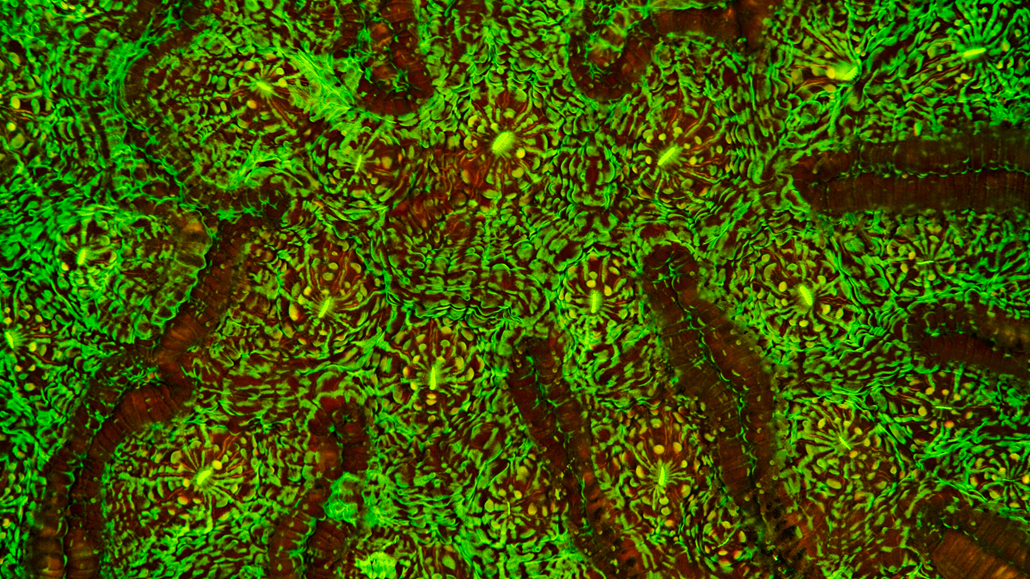

The QE Pro is a high sensitivity spectrometer with low stray light performance. It is ideal for a wide range of low light level applications such as fluorescence, DNA sequencing and Raman analysis.

Although custom QE Pro options are available, you also can choose from among various models -- including several new options -- that are preconfigured for common applications and wavelengths:

- Absorbance

- Fluorescence

- New! General-purpose UV-Vis (200-775 nm)

- New! General-purpose Vis-NIR (350-925 nm)

- New! Extended-range (200-950 nm)

- New! Raman (w/785 nm excitation)

The sensitivity and large dynamic range of the QE Pro combine to make it the highest-performance modular spectrometer in its class. Key features include advanced optoelectronics and thermoelectric cooling to provide thermal stability, and onboard spectral buffering to ensure data integrity at high collection rates.

Product Overview

- New wavelength-specific preconfigured models -- New QE Pro versions for UV-Vis, Vis-NIR and XR (extended-range) measurements (choose Select Model above for details)

- Application-specific preconfigured models -- QE Pro versions for absorbance, fluorescence and Raman

- Sensitive – high quantum efficiency detector

- Powerful – signal-to-noise ratio >1000:1

- Stable – cooled detector allows low light detection and prevents spectral distortion

- Configurable – interchangeable slits, internal shutter (optional) and various gratings

- Buffering -- up to 15,000 spectra

Specifications

Select model to see full specifications

Spectroscopy:

- Wavelength Range:

- 200nm - 1.1μm

- Optical Resolution:

- ~1.2nm FWHM

~1.6nm FWHM

1.70 nm FWHM (typical)

6.87 nm FWHM (typical)

- Corrected linearity:

- 0.5% NL

- Dark Noise:

- 2.5 counts RMS

- Dynamic Range:

- ~85000:1

- Onboard Memory:

- 15000 spectra

- Signal to Noise Ratio:

- 1000:1 (single acquisition)

Detector:

- Pixels:

- 1024

- Detector:

- Back-thinned TE Cooled 1024 x 58 element CCD array

Electronics:

- A/D Resolution:

- 18-bit

- Power Requirement:

- 5VDC 5A

- Strobe Functions:

- continuous and single strobe

Accessories

-

Options available

Prices From $713.00